Corning PCH-01U Pretium Rack Mountable 1U Fiber Optic Splice and Patch Panel Installation

Fiber Optics For Sale Co. carries Corning Rack Mount Fiber Optic Patch Panel in stock.

Or by clicking on on the picture below.

>> General Description

The PCH-01U Pretium rack-mountable housing has a capacity of 96 fibers. It fits into 19-inch rack and occupies 1U (rack unit) space. Here is how the housing looks. The fiber patch panel dimensions are 17 x 12 x 1.75 inch, the weight is 5 lbs.

>> Product Contents:

Here is the list of contents in the package.

- PCH-01U Pretium 1U housing with 2 mounting brackets

- 1x Unit Identification Label

- 2x 10-32 Philips-head screws

- 1x 6-32 Nylon wing nut

- 2x 6-32 Philips flat-head screws

- 4x Cable ties

- 2 feet spiral wrap

- 1 foot double-sided hook-and-loop strap

- 1x Internal strain-relief bracket (cable plate)

- 1x Universal cable clamp (UCC) kit

- 1x Bracket, right UCC

>> PCH-01U Fiber Optic Splice and Patch Panel Installation

>> PCH-01U Fiber Optic Splice and Patch Panel Installation

4.1 Opening the Housing

Removing the cover is optional but is recommended to ease installation

Step 1: Open front and rear doors

Step 2: Locate the plunger fasteners at the front of the unit under the housing cover and pull out to release the plungers

Step 3: Lift stop latches and slide the cover of the unit toward the front until it is clear of the base. Set the cover aside

Step 3: Lift stop latches and slide the cover of the unit toward the front until it is clear of the base. Set the cover aside

4.2 Mounting the Housing into a Rack

Attach the unit to the equipment rack using the four screws provided

4.3 Installing Cable Entry Plate

Step 1: Determine location for cable entry into housing.

Step 2: Slide drawer back completely. The drawer must be in this position to prevent fiber damage during drawer actuation.

Step3: Install cable entry plate using the provided wing nut at the location where the cable will enter the housing

Step 4: Install the strain-relief bracket to the side of the housing at the location where cable will enter the housing.

4.4 Securing the Cable

Note: Fiber optic cable is sensitive to excessive pulling, bending and crushing forces. Consult the cable specification sheet for the cable you are installing. Do not bend the cable more sharply than the minimum recommended bend radius. Do not apply more pulling force to the cable than specified. Do not crush the cable or allow it to kink.

Important: If you are installing outside plant cable or temperature fluctuates widely along any part of the cable, the central member must be strain-relieved. Failure to do so may result in damage to the cable as temperature varies. If the entire length of cable is located in a controlled environment where temperature fluctuation is minimal, it is not necessary to secure the central members. The cable can be strain-relieved by sheath retention alone.

To strain-relieve the cable, use the Universal Cable Clamp (UCC) or cable ties.

4.4.1 Using the Universal Cable Clamp (UCC)

Step 1: Attach the UCC clamshell to the strain-relief bracket as shown in Figure 5 to allow installation of a second UCC if necessary.

Step 2: Follow installation instructions provided with the UCC kit to secure the cable. Do not tighten yet to allow for cable adjustment if necessary.

Step 3: Secure cable to cable entry plate using a loose cable tie. Do not over-tighten cable tie.

4.4.2 Using Cable Ties

Step 1: Attach the cable with cable ties to the strain-relief bracket in two places as shown in Figure 6.

Step 2: Allow room on the bracket to strain-relieve the cable strength member, if present.

Step 3: Secure cable to cable entry plate using a loose tube tie. Do not over-tighten cable tie.

4.4.3 Strain-relieving the Cable Central Member

Step 1: Install the U-shaped washer and the flat washer on the strain-relief bracket in the orientation shown in Figure 6 using the supplied Philips-head screw.

Step 2: Place the central member and yarn, if present, between the U-shaped washer and the flat washer.

Step 3: Wrap yarn in a clockwise direction around the screw and under the U-shaped washer.

Step 4: Tighten the screw.

Step 5: Trim off the excess yarn and central member.

4.4.4 Grounding Armored Cable

One grounding kit (part number FDC-CABLE-GRND, purchased separately) is required to ground each armored cable. Follow instructions provided with the grounding kit.

Step 1: Attach the other end of the ground wire to the equipment rack. The equipment rack must be grounded to the primary building ground.

Step 2: Remove the paint from the frame at the grounding location to ensure metal-to-metal contact. It is recommended to use an antioxidant on the bare metal to prevent corrosion.

Step 3: Or, attach the other end of the ground wire to a rack-mounted grounding bus bar, which is grounded to the primary building ground.

4.5 Managing Cable

4.5.1 Installing Preconnectorized Cable

Step 1: Clean connectors and adapters.

Step 2: Install connectors into the adapters at the rear of the connector panels.

Step 3: Route cable slack around radius control guides (Figure 7)

Step 4: Use cable ties through the lances to secure fibers as needed.

Important: Lift the tray stop latches and slide the drawer backward and forward to verify that the drawer slides in the grooves of the guides and that there is enough fiber slack to prevent violating the minimum fiber bend radius of the cable.

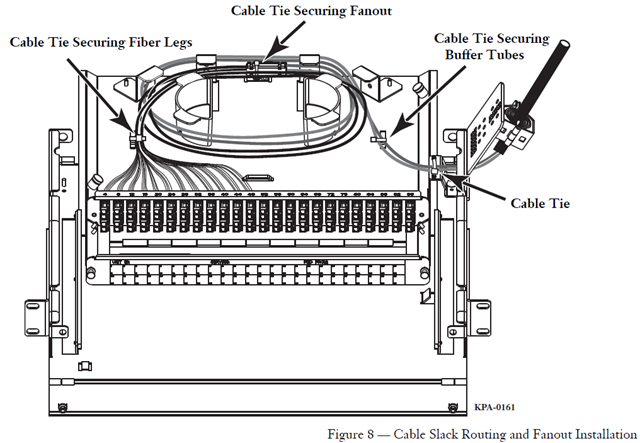

4.5.2. Installing Cable Using Buffer Tube Fanout (BTF) Kits

4.5.2. Installing Cable Using Buffer Tube Fanout (BTF) Kits

Step 1: Terminate the fibers according to the instruction provided with the Buffer Tube Fanout (BTF) kit.

Step 2: Feed the fanout body and connectors through the cable entry opening.

Step 3: Slide the drawer back completely and loop the buffer tube under the fanout bracket and around the radius control guides. Secure the BFT truck body to the fanout bracket using a cable tie. (Figure 8)

Step 4: Route the connectorized fibers under the plastic tabs on the radius control guides

Step 5: Remove the caps from the connectors and adapters into which they will be mated. Clean both connectors and adapters. Mate the connectors in the adapters.

Step 6: Use cable ties through the lances to secure fibers as needed.

4.6 Documentation

Record fiber identification information appropriately on the identification label (Figure 9). The identification panel can be removed, if desired. Accurate recordkeeping is imperative for an organized installation.

4.7 Closing the Housing

Step 1: Lift up on stop latches and slide drawer forward to make sure cable is not stressed. If necessary, readjust cable strain-relief to prevent stress on fibers. Tighten UCC clamp.

Step 2: Slide drawer back to original position.

Step 3: If previously removed, slide the cover back in the retaining flanges on top of the housing. Push the plunger fasteners to secure

Step 4: Close the front and rear doors.

4.8 Install Jumpers

Step 1: Remove dust caps from the connectors and adapters into which they will be mated. Clean all connectors and adapters.

Step 2: Install jumpers as specified on planning diagrams. The panel can be raised to access the adapters on the bottom row. When raising the panel, the cover must be removed to prevent damage to the connectors on the back side of the panel. Cut the provided hook-and-loop strap into small sections and feed the strap through the appropriate lance at the front of the housing. Loosely secure jumpers using the straps at the front of the housing. (Figure 10)

Step 3: Provide enough jumper slack to allow the connector panel tray to slide backward and forward without violating the minimum bend radius of the jumper.

Step 3: Provide enough jumper slack to allow the connector panel tray to slide backward and forward without violating the minimum bend radius of the jumper.

Step 4: Record jumper routing information on the provided identification sheet. The identification panel can be removed, if desire. Accurate recordkeeping is imperative for an organized installation.

>> Connector Care and Cleaning

- Always keep dust caps on connectors and adapters when not in use

- Ensure dust caps are clean before reuse.

- Use optical cleaning materials as standardized by your company

- Clean the connector before every mating, especially for test equipment patch cords (jumpers)

- A minimum level of cleaning is listed below. Local procedures may require more rigorous cleaning methods

Step 1: Remove plugs from the connector adapter.

Step 2: Wipe the connector ferrule twice with a lint-free wiping material moistened with isopropyl alcohol. Then wipe across the end of the ferrule.

Step 3: Repeat previous step with a dry wipe.

>> Testing

6.1 Provisioning Tests

Equipment should be tested from the source (or central office) to receiver at the time of provisioning to verify signal continuity and acceptable loss limits. Use an optical power meter to verify signal continuity and determine loss measurements are within specified local standards.

6.2 Troubleshooting Tests

An optical power meter can be used to perform the first step in troubleshooting. A power meter designed for measuring only dBm power levels is suitable for maintenance purposes.

For high attenuation:

- Remove connector and reclean connector and adapter

- Verify cable ties are not too tight

- Maintain appropriate fiber bend radius. Make sure there are no sharp bends

Once a fault is isolated to the installed cable link, an OTDR is needed. An OTDR can locate fiber events and measure the losses attributable to cable, connectors, splices, and/or other components. The graphical display of loss over a cable’s entire length provides the most revealing analysis and documentation available on a cable link, commonly referred to as its signature trace. It is recommended to perform an OTDR analysis to document the integrity of the cable system, locate and measure each event or component, and uncover faults throughout the cable. Follow the instructions provided with the OTDR tester you are using.