Fiber Optic Cable Test After Shipping and Handling

OK. Here is the point: fiber optic cables should be tested after shipping and handling. This is one of the most common mistakes made by fiber optic cable installers and contractors.

Damage to cabling can occur during shipping or installation. Failing to test fiber cables after it is delivered is a common mistake made by installers. This failure makes damaged cable detection difficult and returns awkward.

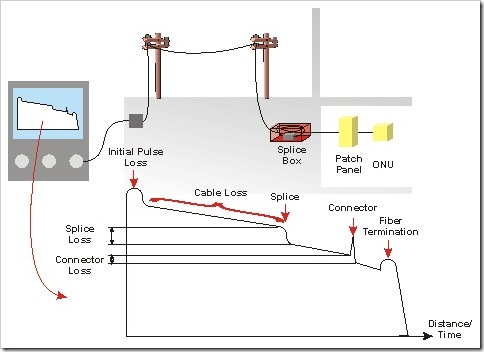

An OTDR could be used in this case to shoot an optical profile on each fiber after the cable is received and still on the shipping reel. A permanent record will then be available for future use.

Failing to perform testing, verification, and documentation prior to the installation of the fiber end-termination equipment is a problem. If the fiber is not tested after installation, it cannot be determined whether it was installed correctly; serious equipment performance problems can occur.

Furthermore, failing to document in the cable plant could make trouble-shooting difficult later; as well as voiding warranty conditions of the installed network.

When testing short runs of fiber, there is typically not much information about the fiber available except for length and attenuation. Connectors and splices are generally not present, needed, or used for short lengths; new short runs would be reinstalled.

The sampling rate of an OTDR will determine how much resolution the instrument has when capturing trace information. While it is important to maximize resolution for short distances, it is not mandatory for longer distances.

Since it takes more time to take more sampling or data points, longer stretches of fiber can use a lower sampling rate, whereas medium lengths can use a medium sampling rate. This kind of incremental improvement in time helps when testing hundreds of fibers.